When we think about diesel engines today, we need to think beyond the primarily mechanical workhorse of years past. Over the last two decades, the diesel engine has evolved to include many software controlled electronic systems (fuel, aftertreatment & emission control).

Just like we change oil, filters and lubricate chassis components as a way of maintaining reliability of mechanical components, we also need to update Engine Control Module (ECM) software to improve reliability and performance of electronic systems.

Over the past 4-years advising and training fleet maintenance professionals, we have identified many opportunities for downtime reduction, efficiency improvements and cost reduction. One opportunity common to almost every fleet operating Cummins powered equipment, is the integration of regular ECM Calibration Updates into the current PM schedule.

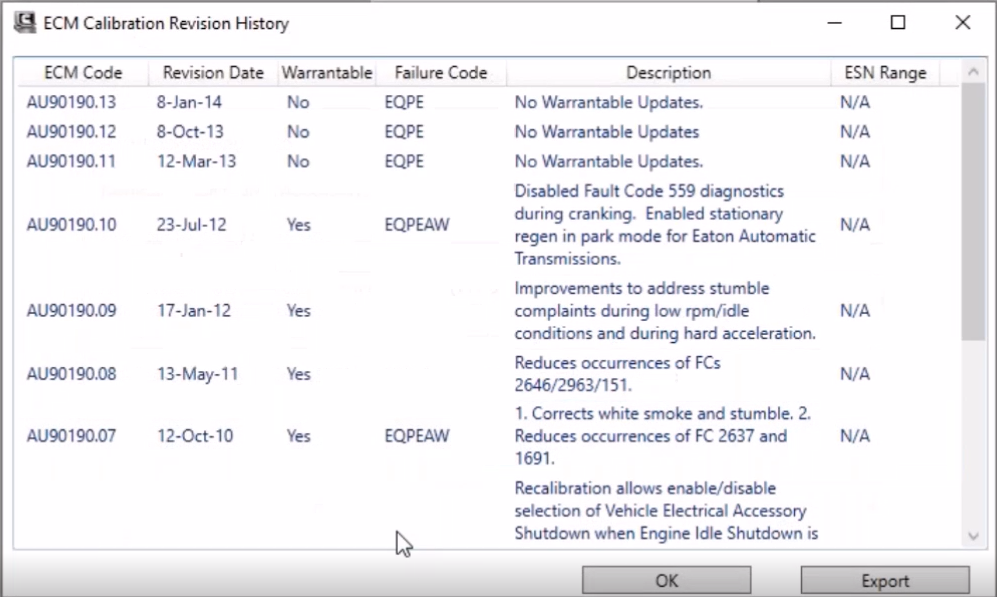

Like the apps on your smartphone or the operating system on your laptop, we often require updates, most of which are described as: “Performance Improvements and Bug Fixes”. When looking at Cummins ECM Calibration Update descriptions, they are no different. Majority of the updates claim to reduce occurrences of fault codes and improve performance of systems. Some common Cummins ECM Calibrations (ISX15 calibration codes CL10042 & EF10047) show a new update released as frequently as once every three months.

Like the apps on your smartphone or the operating system on your laptop, we often require updates, most of which are described as: “Performance Improvements and Bug Fixes”. When looking at Cummins ECM Calibration Update descriptions, they are no different. Majority of the updates claim to reduce occurrences of fault codes and improve performance of systems. Some common Cummins ECM Calibrations (ISX15 calibration codes CL10042 & EF10047) show a new update released as frequently as once every three months.

For a fleet operator and maintenance provider, keeping this engine ECM software current and up to date is an effective way of proactively reducing the occurrence of many fault codes and eliminating associated downtime and repair costs.

We encourage every fleet to consider integrating ECM Calibration Updates into the preventative maintenance schedule as a way of increasing reliability and vehicle uptime. For information on locating Cummins ECM Calibration information or obtaining authorization to purchase INSITE Pro, required for downloading and installing calibration updates, please contact VieTech Training & Consulting Inc.

About VieTech Training & Consulting Inc.

At VieTech, we believe that employee skill development is integral to maintaining a safe, productive and rewarding work environment. With the fast pace of business today, skills training needs to be accessible, relevant and empowering. VieTech delivers on-site, on-time and on-budget skills development training for the automotive and heavy-duty service industry.

VieTech’s Diesel Engine Technology Fundamentals training program helps reduce outsourced repairs and related downtime for your diesel fleet. Service technicians will gain the in-depth fundamental knowledge of modern complex fuel and emission control systems and electronic tools that are necessary for proper and effective troubleshooting and repair. Unlike OEM training, our courses are designed to be delivered on-site, on-line, on-time and on-budget to meet the demands of your busy operation. Diesel Engine Technology Fundamentals helps develop the core-competencies that directly translate to on-the-job performance improvement for your technical employees.